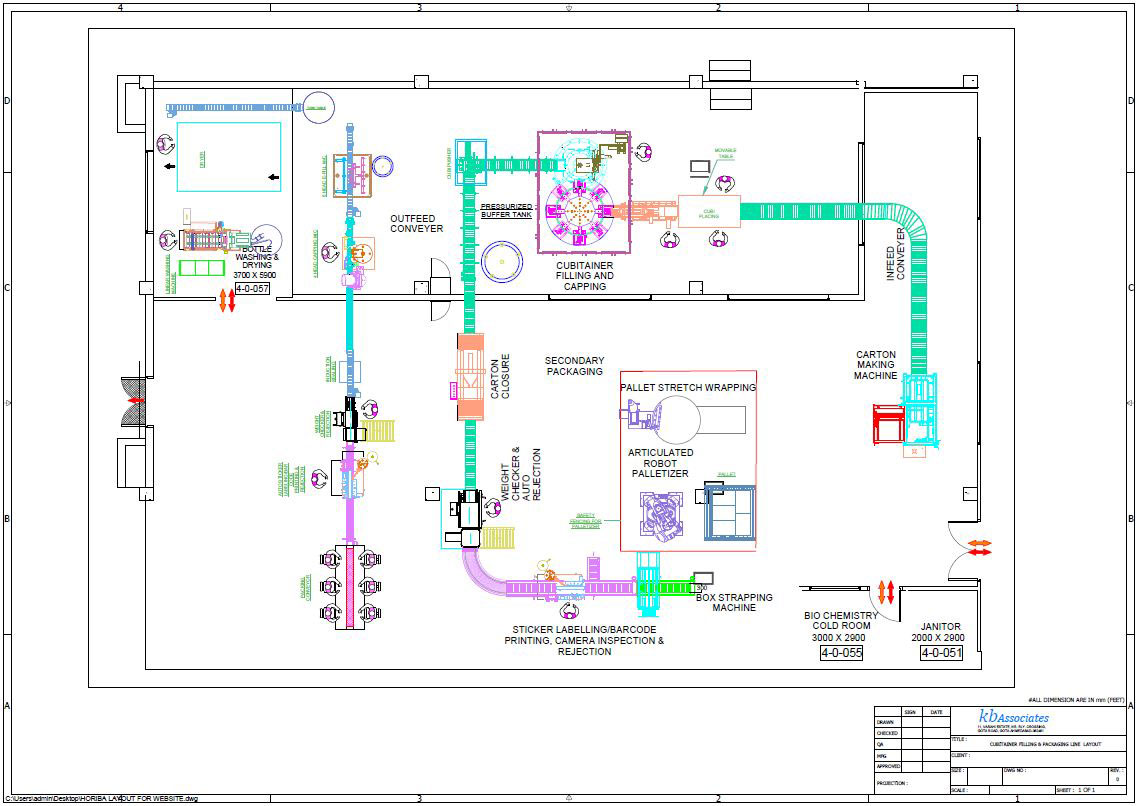

Box opening & sealing machine

A Box/Carton opening sealing machine or cartoner is a packaging machine that forms cartons: erect, close, folded, side seamed and sealed cartons. Packaging machines that form a carton board blank into an open box carton. The offered carton sealing machine is easy to operate and suitable for wide range of box sizes.

Cubitainer filling & capping machine

Cubitainer filling is a wide range of liquid filling machines for cubitainer/ politainer. Consist of a filling & capping carrousel on single frame. Available with different combinations in semi-automatic & fully automatic segments with output from 40 to 400 cubitainer per hour.

Key Feature

- Filling liquid supply by pressurized tank with Consistent product flow rate even with viscosity variations.

- Electromagnetic Flow meter based filling system with specialized end shut off zero dripping nozzles which gradually fills cubitainer bag from bottom.

- Also available with nitrogen purging to prevent product contamination.

- Servo based capping system with torque measurement & control for uninterrupted production.

- Fully automatic 2 tanks clean in place system with customized cleaning programs.

Box closing & sealing machine

A box/carton closing with flap closure first close the box from all sides & tapping on it. To make box tamper proof. Almost all random sizes boxes are closed & tapped with single machine.

Sticker Labelling machine with camera inspection & automatic rejection

Self-adhesive sticker labelling with barcode/QR code printing is one stop solution for print, batch code, manufacturing date, barcode, QR code & affixing onto the box.

After labelling smart camera inspection system monitors the Barcode / QR code & if found incorrect the box will be rejected & reused.

Box Weight checker & automatic rejection

The Dynamic Weighing Systems – check weight systems, are widely used for checking the weight of filled pack and segregate the overweight and underweight packs. These systems are highly effective and helping tools where the packing speed is too high to avoid manual error. This helps the manufacturer to keep the track of line so that pack with correct weight will reach the market and eliminate the complaints from the market.

The check weight systems are based on the HMI and ARM technique and hence offer very precise settings and operations.

Box Strapping machine

Automatic Strapping Machine is an advanced packaging machine, which makes use of flat & plastic steel bands. It can be tightened around the package and efficiently used to secure the package. Automatic Strapping Machine can bundle the products together and can boost the containment strength. This is also used to secure the load to a shipping pallet. It has the capacity to combine, reinforce, stabilize, fasten and hold the items.

32

32