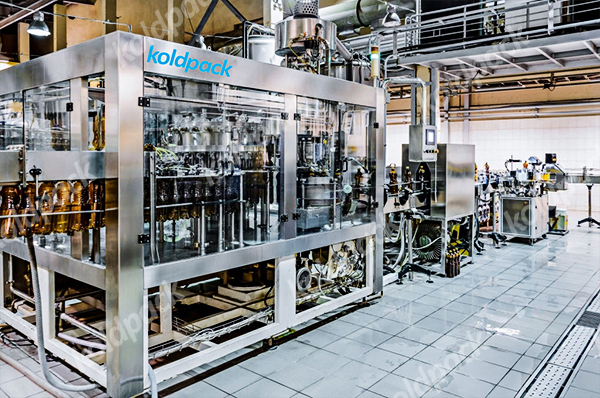

The quality of juice is not only defined by its taste but also by the feeling in the mouth. The Koldpack dosing systems are the solution for all bottling plants that strive for top product quality and wish to lean on a high-standard premium fruit juice production with hygienic filling lines as compared to the conventional hot filling process.

| Model | KRFC-60-HYGEINE FILL | KRFC-90-HYGEINE FILL | KRFC-120-HYGEINE FILL |

| No. of Heads | 12-12-12-6 | 16-16-16-8 | 20-20-20-10 |

| Output @ 200/250 ml. in (bottles per minute) | 60 BPM | 90 BPM | 120 BPM |

| Output @ 600/750 ml. in (bottles per minute) | 35 BPM | 50 BPM | 60 BPM |

| Sterilization | PAA (parasitic acid) with sterile Hot water | PAA (parasitic acid) with sterile Hot water | PAA (parasitic acid) with sterile Hot water |

| Cap Sterilization | Immersive/Spray PAA sterilization with sterile water spray wash | Immersive/Spray PAA sterilization with sterile water spray wash | Immersive/Spray PAA sterilization with sterile water spray wash |

Dual rinser station for PAA /H2O2 sterilization & Hot Sterile Air/Water sterilization for container sterilization.